In dust collection, the collector must work to move large amounts of air at high speeds; capturing it at the tool, pulling it through the ductwork, spinning it into the cyclone, and finally pushing it back out through the filter – all without releasing any dust into the environment. To do this the dust collector needs to provide sufficient airflow (CFM) to each connected tool and must overcome several resisting forces.

Whether or not the air is clean or laden with dust, all air has mass. This means that as it moves, frictional forces slow it down. Making matters worse, friction increases as the air's mass and speed increase. Friction is created by the air interacting with other materials, including the dust within it, the components it moves through (e.g. hose, ductwork, etc.), and the air itself. The total degree of resistance within this airstream is referred to as static pressure (SP) and it is often measured in inches of water column pressure (WC).

How Does Static Pressure Affect Dust Collection Performance?

Every dust collector has an airflow rating, usually written in the form of x CFM at y WC, that indicates the total volume of air being moved through the dust collector against a specific resistance. When the collector turns on, its fan starts rapidly spinning and pushing air through the system, creating a negative pressure zone inside the collector. All of the air connected to the dust collector immediately starts moving towards this area to balance the pressure zones and reach equilibrium; this is what creates the "suction force" that pulls air from the tool and keeps it clean of dust and debris.

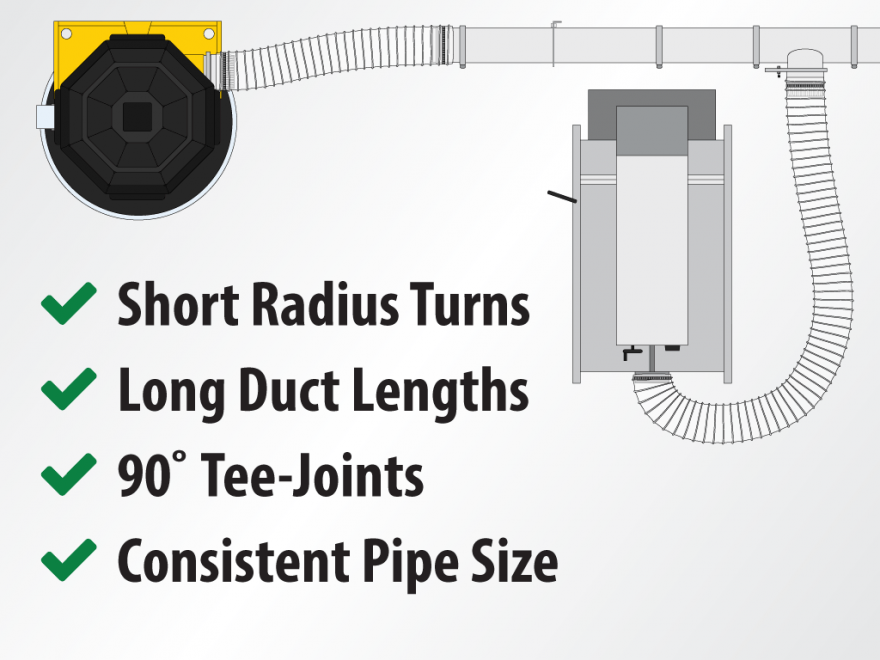

Working against this airflow is the positive pressure being created within the ductwork - commonly referred to as static pressure loss. Every component that the air moves through will increase the frictional forces acting upon the air and reduce the air's velocity. Certain components are more detrimental than others. In general, the more turbulence a component introduces to the airstream – whether by having a rougher surface area (like flex hose) or by joining multiple airstreams together (like wye joints) – the more resistance it creates.

See below for a data table of common pressure loss values for each ducting component:

Static Pressure (Air Friction) Losses Measured in Ducting

| 3" Dia. | 4" Dia. | 5" Dia. | 6" Dia. | 7" Dia. | 8" Dia. | |

|---|---|---|---|---|---|---|

| 5 ft of Rigid Pipe | 0.355" WC | 0.285" WC | 0.230" WC | 0.185" WC | 0.145" WC | 0.115" WC |

| 1 ft of Flex Hose | 0.352" WC | 0.280" WC | 0.225" WC | 0.180" WC | 0.141" WC | 0.108" WC |

| 90° Elbow | 0.470" WC | 0.450" WC | 0.531" WC | 0.564" WC | 0.468" WC | 0.405" WC |

| 45° Elbow | 0.235" WC | 0.225" WC | 0.266" WC | 0.282" WC | 0.234" WC | 0.203" WC |

| 45° Wye Branch | 0.282" WC | 0.375" WC | 0.354" WC | 0.329" WC | 0.324" WC | 0.297" WC |

| Static Pressure loss values are representative of airflow at sea level moving at 4000 FPM. | ||||||

In ducting layouts, the pressure loss is cumulative along an entire run from the tool to the collector's inlet. If the total pressure loss in the system is too great, then the airflow will be insufficient to move the dust within it, leaving a mess on the tool and in the ductwork. For this reason, all Oneida Air Systems dust collectors include a fan performance curve which graphs the expected airflow at any static pressure. With a fan curve, shop owners can estimate performance once the system and ductwork are all assembled and design according to these limitations.

Does Altitude Affect Static Pressure Loss?

While air is indeed thinner at higher altitudes, it would be incorrect to say it negatively affects static pressure loss. Because the air is thinner, the dust collector's fan blower must be larger (both in terms of horsepower and impeller size) to move the same amount of air as it would at normal altitudes. However, the thinner air also means that the effects of positive pressure build-up within the ducting are lessened as well.

In other words, shop owners do not necessarily have to change their ducting plans to accommodate differences in altitude. They will, however, need a more powerful dust collector. Here is a table illustrating the CFM correction factor for increasing altitudes (planning for the worst case scenario).

For example, if you had shop that would normally be sized for a 2HP dust collector, but it's located at 9,000 ft in the Rocky Mountains, you would instead need a 3HP system to provide sufficient CFM to your tools (2HP x 1.48 = 2.96HP ≈ 3HP).

| Altitude Above Sea Level | HP Correction Factor |

|---|---|

| 1,000 ft | 1.03× |

| 2,000 ft | 1.07× |

| 3,000 ft | 1.10× |

| 4,000 ft | 1.12× |

| 5,000 ft | 1.16× |

| 6,000 ft | 1.21× |

| 7,000 ft | 1.27× |

| 8,000 ft | 1.35× |

| 9,000 ft | 1.48× |

| 10,000 ft | 1.64× |

How is Static Pressure Measured?

To find the static pressure of a dust collection system, we need to measure its negative pressure zone relative to the ambient air inside the shop – like how a tire's positive air pressure is rated relative to air outside its steel and rubber walls. And just as there are different scales to measure temperature by (e.g. Fahrenheit, Kelvin, etc.), there are also a variety of ways in which we can measure air pressure. In dust collection, since air pressures are still relatively low compared to what might be inside a car tire, we use what's called a manometer to find how the pressures affect a volume of water - giving us a reading shown as inches in water column (WC).

How Does A Manometer Work?

A manometer is a fairly simple tool: a U-shaped hose laid over an imperial ruler. The bottom of the "U" is filled with a small amount of colored water, while the hose ends are connected to the two different pressure zones. Where a dust collector is concerned, one end of the manometer is open to the air in the shop, while the other end is inserted into a length of straight pipe connected to the collector's inlet. The fan motor's negative pressure zone creates a vacuum inside the manometer, drawing the water inside the hose up one side of the "U" and down the other. The distance between the two heights of water in the hose shows the system's static pressure rating.

There are also digital manometers, which are much more compact, more precise, and can provide measurements on alternate pressure scales (e.g. psi, kPa, inHg, etc.). Oneida Air Systems uses a digital manometer with a pitot tube inserted into 10 feet of ducting connected to the collector's inlet to measure the air specifications for all of our systems.

1 psi = 2" Hg = 27.7" WC