Commercial cabinetry and milling companies produce wood dust constantly and in high volume. At scales such as this the downtime for emptying large 55-gallon barrels becomes prohibitively expensive quite quickly. That's why Oneida Air Systems is the manufacturer of choice for bulk waste handling needs.

Here you'll find photos of the custom dust collection configuration at a local millwork company. This is one of several Oneida Air systems at their location, utilizing our industrial 10HP Direct Drive Dust Collection system on their large planer. The planer's dual dust ports were the first tool connected to this collector, prioritizing the most airflow to the largest dust producer on the ducting run. Waste from this and other tools is collected at the cutter head and continuously fed to an external container outside the building for processing.

Products and Services Used:

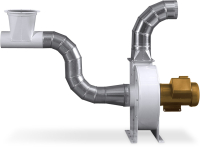

- 10HP 230 3-phase Direct Drive Cyclone Dust Collector w/ Rotary Air Lock Valve

- Custom Built Cyclone Expansion Chamber

- 5HP 3-phase Transfer Blower Kit

- Heavy-Gauge Snap Lock Ductwork

- Duct Design Service

Oneida Air Systems does not provide installation services. Because this company was local to, our technicians were able to provide both direct and remote consultation services as needed.