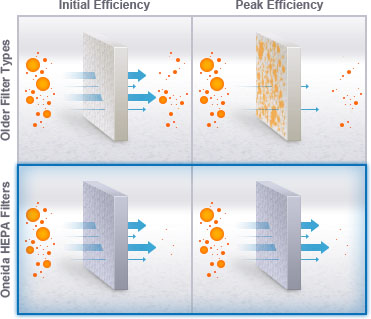

The filter media is the main component that makes up an air filter. Older style filter medias (including nanofiber, cellulose, blended, spunbond, etc.) only reach peak particle efficiency after the filter has been "seasoned" for a period of time to develop a thick layer of very fine dust, known as filter cake, over the media. There are a few problems with this principle.

First, there is a significant suction loss once the filter cake is sufficiently thick, meaning that there is no way to both have peak filtration and maintain an effective suction level with an older filter media type. Second, a normal wood-working environment will not generate the uniform layer of dust buildup used in manufacturer testing; recreating that layer can be difficult, wasteful, and inefficient. Finally, air filters require regular cleaning which removes the layer of filter cake. You’ll have to go through the buildup process all over again every time you clean the filter.

Oneida Air Systems' HEPA-Grade Media Cartridge Filters work at peak efficiency right out of the box and will return to that level of filtration after repeated cleanings. The filters are fully washable, are easy to clean, and have a balance of high filtration efficiency and low pressure drop. Our filters are manufactured with HEPA-Grade ePTFE (expanded polytetrafluoroethylene) media - a quality certified product. Here at Oneida Air Systems, your health and safety are paramount where our filters are concerned.

Initial Efficiency Tests

In order to compare Oneida Air Systems' HEPA-Grade Media Cartridge Filters to older media types, each filter was purchased on the open market by an accredited 3rd party lab and was tested with the same experimental setup and variables. Below you can see comparative results for each filter’s efficiency on an initial load (before a layer of filter cake could be established). In the time it takes older filters to build up a layer of filter cake, a large amount of fine dust particles are released back into the air.

Efficiency After Consecutive Loads

It can take numerous workloads for the dust collection system to capture enough dust to develop a layer of filter cake sufficient for healthy particle removal. In this test, an accredited third party lab ran five consecutive loadings of test dust through the Nanofiber Cartridge Filter (a total of 766 grams of dust) at 500 CFM and measured its filtration efficiency rate for each load. As seen in the graph, it took over four loads to reach a healthy particle removal rate; even then, the filter did not reach the same level of filtering efficiency that Oneida Air Systems' HEPA-Grade media filter had initially.

Efficiency Before & After Cleaning

Filter cleanings are important when considering older styles of filter media. In this test, the initial particle removing efficiency of the Nanofiber Cartridge Filter was compared to its efficiency after a full cleaning. As seen in the graph, cleaning the filter lowered its particle removal efficiency rate down to nearly base levels. These results are indicative of how the filter would perform after routine cleaning.

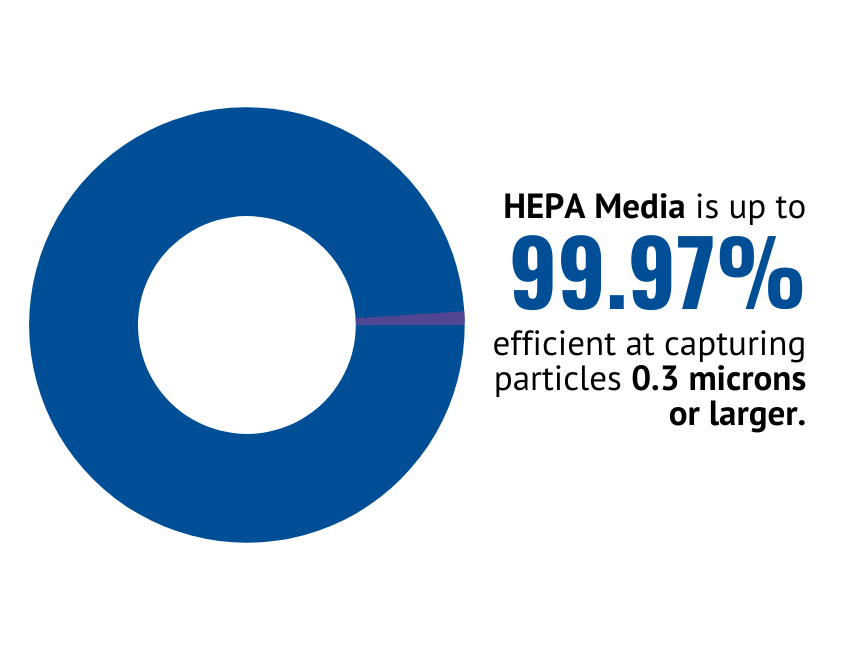

Health & Safety

Over time, these differences in performance can have a huge effect. Experts agree that good dust collection requires almost 100% efficiency to prevent the most damaging respirable particles from being inhaled. Particles with a diameter of 10 micrometers or less, referred to as being in the PM-10 range, can become lodged deep down inside the tissues of the lungs where it is very difficult for them to be expunged (see figure). Fine dust can also cause equipment failure and create workshop hazards.

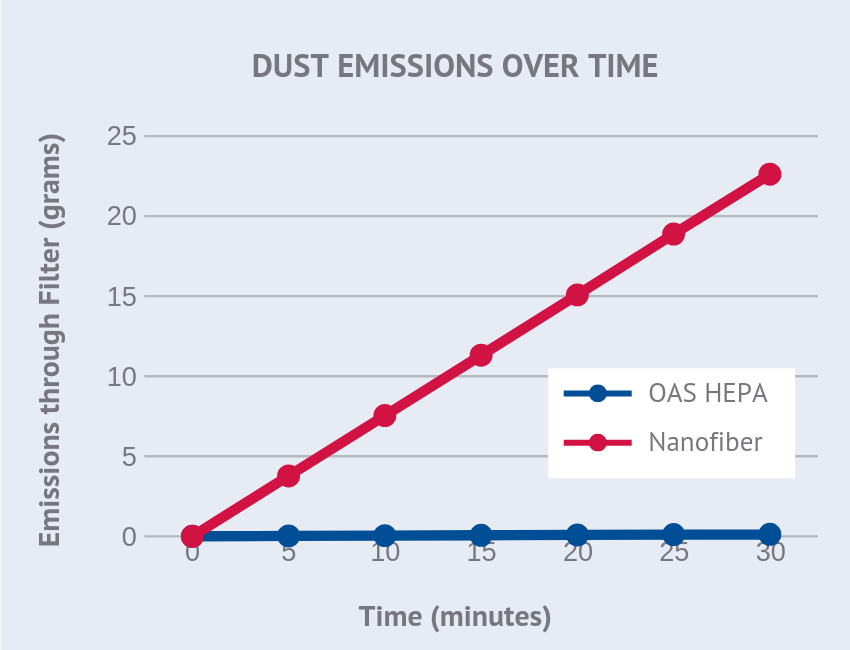

Imagine if 10 g/min of PM-10 dust went into both the Nanofiber Filter (with an Average Initial Efficiency of 92.46%) and the Oneida Air Systems HEPA-Grade Media Filter (with an Average Initial Efficiency of over 99%) for just 30 minutes. The Nanofiber filter would release 99.4% more particles than the Oneida Air Systems HEPA-Grade Media Filter. That’s 22.625g of dust from the Nanofiber Filter - enough to fill ¾ of a typical 1oz. salt shaker - coating the inside of your lungs.

Performance Over Time

In May of 2013, WOOD Magazine published a study analyzing the filtration efficiency of various dust collectors by popular brands. They "seasoned" all of the filters by sucking up dust generated from a drum sander repeatedly being used on a 12"x48" MDF sheet (in order to replicate long term use). A digital particulate meter was used to measure the number of airborne particles (larger than 1 micron in size) after each MDF sheet was passed through. As seen in the chart, Oneida Air Systems' dust collector outperformed the rest of the competition thanks to its patented cyclone design, high-quality American-made components, and HEPA-Grade Media Filter. Removing airborne particles in the PM-10 range allows you to work longer and safer in the shop without discomfort.