The dust collector itself is only one part of an efficient dust collection system. An airtight and optimized ductwork layout is essential to maximize your shop's performance. Oneida Air Systems has put together a guide designed to provide a basic understanding of dust collection airflow and the components required to successfully complete an entire ductwork installation. Each section of this blog series will take you through the processes of preparing, assembling, and connecting your ductwork.

Once you have begun your ductwork layout, you can start to assemble your Quick-Clamp Ductwork.

Using Quick-Fit Clamps

To connect Quick-Clamp Duct pieces, wrap a Quick-Clamp around the rolled ends of two connecting pieces and snap the clamp closed. When clamped together, the pipes and fittings form an air-tight seal.

The Quick-Fit clamps are designed to provide a tight seal, which means that they also require some pressure to close. By pre-stretching the clamp, you can make it much easier to close when you connect two pieces together.

After closing each clamp, be sure to install one of the enclosed cotter pins into the hole. This ensures that the clamp cannot come open unexpectedly.

Installing an Adjustable Sleeve

During installation, there will be times when you’ll need less than a full 5’ length of pipe to accommodate your design. In those cases, you’ll need to cut the pipe to shorten it and then connect it to an Adjustable Sleeve to ensure an airtight seal. Adjustable sleeves also allow up to 11” of movement, which is useful for making small adjustments to connect to tools or ducting drops.

You can find video instructions for installing an Adjustable Sleeve here.

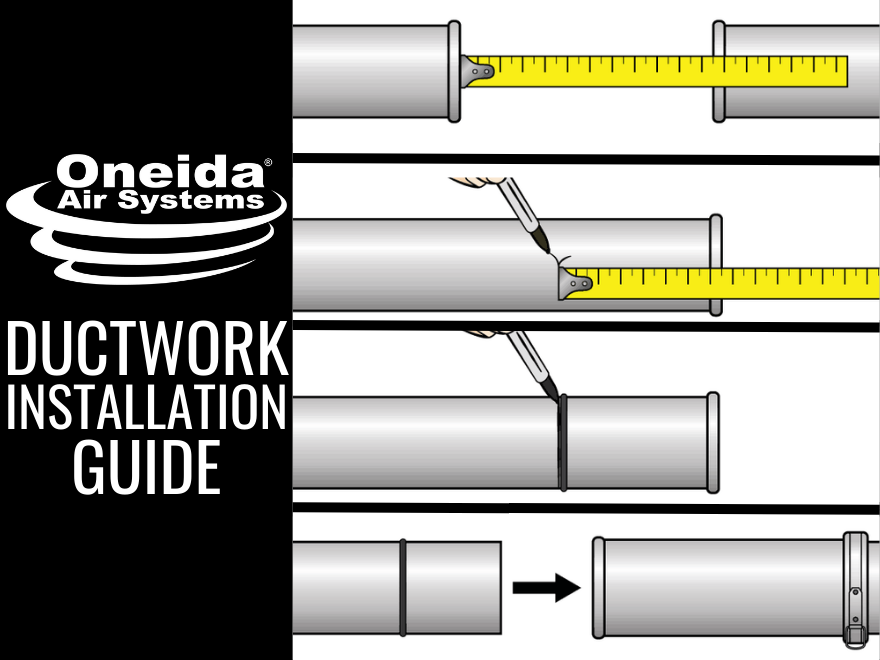

First, measure how long your shortened pipe section needs to be.

Mark the pipe approximately 4" shorter than your measurement.

Use the O-Ring provided with the Adjustable Sleeve to mark the cut.

Move the O-Ring away from the marked line and cut the pipe (NOT the Sleeve). To make removal easier, either cut off sections as you continue or rotate the duct around to start on the other side.

Make sure that the ducting maintains its round shape. Once you're done cutting, be sure to file and/or deburr the sharp edges so that there are no rough parts that could grab or snag airborne dust and debris.

Slip the cut end of the pipe into the Sleeve. Be sure that the 11" Sleeve is downstream of the cut piece.

Slide the O-Ring until it is seated against the rolled edge of the sleeve. The O-Ring will form a seal and provide a rolled surface for the Clamp to grab onto.

Finally, use a Clamp to connect the rolled edge of the Sleeve and the O-Ring together. Once in place, you can re-adjust the length of the assembly by releasing the clamp and changing the length of the pipe that is inserted into the Adjustable Sleeve.

Adding Wye Joints

To ensure proper airflow performance, Wye Joints must be oriented so that the branch segment is pointing off and away from the direction of airflow (i.e. do not point the branch "jackknifing" back towards the dust collector).

Adding a Saddle Tap Wye

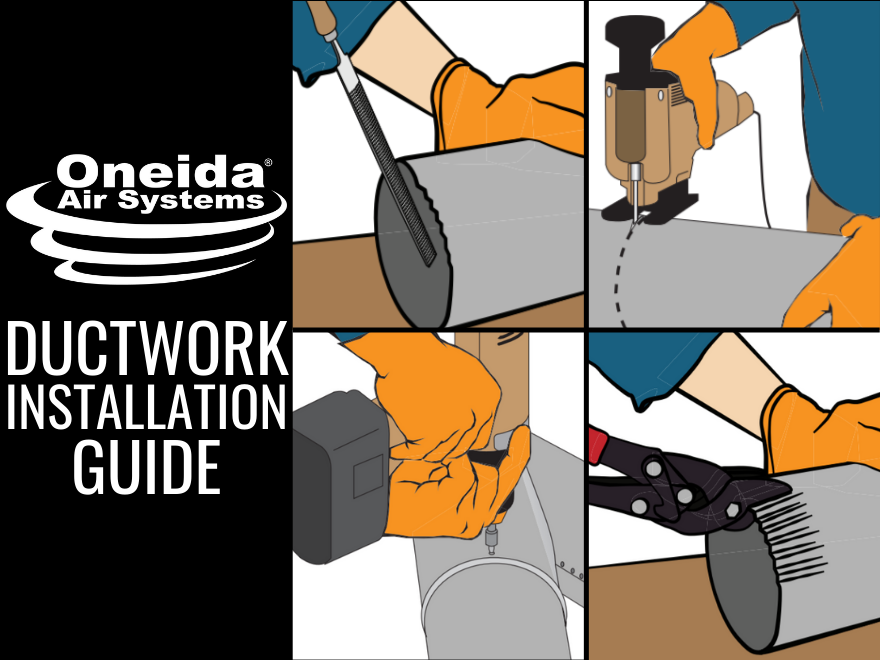

First, lay the Saddle Tap Wye in the correct orientation (pointing away from the direction of airflow) and trace the egg shape onto the pipe from inside the branch.

Next, drill a pilot hole using a stepped drill bit to create a starting place for cutting.

Cut out the shape that you drew and peel the sheet metal back as you cut. Once cut, be sure to file and/or deburr the sharp edges so that there are no rough parts that could grab or snag airborne dust and debris.

Lay the Saddle Tap Wye onto the pipe and align the branch with the hole that you cut. If it's not aligned properly, the airflow efficiency will significantly decrease at the branch.

Secure the Saddle Tap Wye to the pipe in a minimum of four locations with self-tapping screws or pop rivets, starting with the end at the bottom of the egg shaped hole. Use silicone or adhesive-backed aluminum tape to create an airtight seal.

Adding a Clean Out

To add a Clean Out, first lay it on your pipe in the desired location. Then open the Clean Out, and trace the inner oval shape onto your pipe

Drill a pilot hole using a stepped drill bit to create a starting place for cutting, and cut out the shape that you drew.

Peel the sheet metal back as you cut. Once cut, file and/or deburr the sharp edges to ensure that there are no rough parts that could snag airborne debris.

Lay the Clean Out back onto the pipe and align it with the hole you cut. Secure it in place with self-tapping screws or pop rivets, and use silicone to create an airtight seal.

Sealing the Main Line

You can seal off the Main Line of your ductwork assembly using an End Cap. Simply push the End Cap firmly into the open pipe end, then secure it in place using Foil Tape.

What's Next?

Looking for more help with your ductwork installation? All of our large ductwork orders and ductwork kits now include a copy of our complete Ductwork Installation Guide, which goes into detail on each step of the process.